What sparked the conversation?

A recent LinkedIn post by Kenneth Shultz, PE, lit up the MEP community. He shared photos from a project where the contractor used flexible ductwork in place of rigid metal duct to shave $3,000 off the budget. The flex duct was snaked through tight joist webs—but the bends were so severe, some air registers were barely getting airflow. To make matters worse, the contractor had removed Testing, Adjusting, and Balancing (TAB) from the project scope. That meant no one would know if each room was getting the proper airflow—until tenants started complaining.

That post hit a nerve. Engineers, installers, and commissioning pros flooded the comments with war stories. The theme was clear: when misused, flexible ductwork can quietly sabotage your HVAC system—and skipping TAB removes your safety net.

"That $3K savings just became a $15K+ tear-out special."

— Kenneth Shultz, PE

What Is Flexible Duct and Why Is It Controversial?

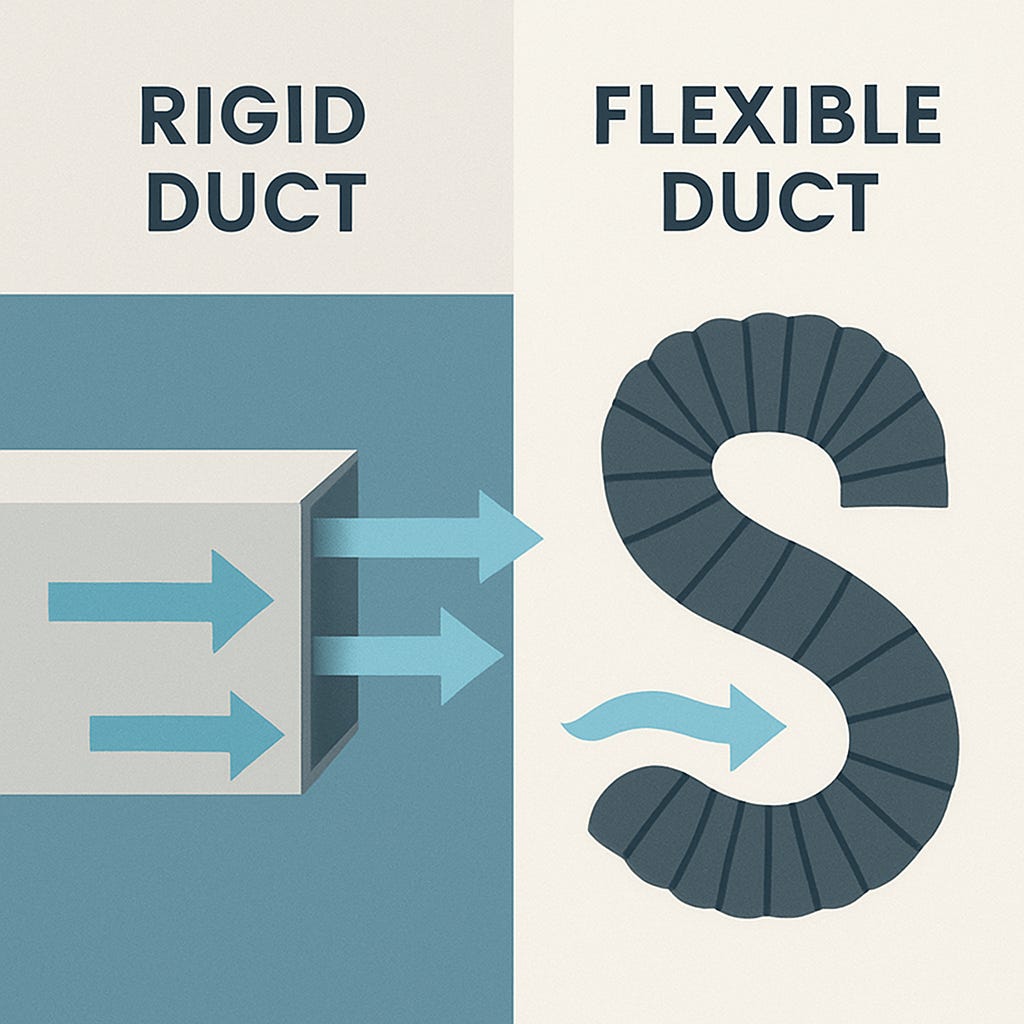

Flexible ductwork is a factory-made, bendable duct often connected to a rigid metal trunk to a ceiling diffuser or grille. It’s cheap, flexible, and easy to install—especially in tight spaces. But it comes with severe limitations:

📏 1. Keep It Short

Most codes and standards cap flex duct runs at 5 to 6 feet.

Chicago Mechanical Code: “Shall not exceed 6 feet.”

University of Washington Design Standards: Max 6 feet and only one elbow.

You’ll see this in any halfway decent set of HVAC drawings.

🧱 2. Support It Properly

The American Society of Home Inspectors recommends:

Horizontal supports every 5 feet

Vertical supports every 6 feet

Limit sag to ½ inch per foot

➰ 3. Avoid Compression and Kinks

According to installation manuals:

Duct must be fully extended, not bunched or kinked.

Each 90° bend acts like 20 feet of extra duct.

A 180° bend can act like 40 feet of duct.

The Cost of Cutting Corners

That $3,000 in material savings can lead to:

🔻 Reduced airflow (rooms don’t heat/cool properly)

⚠️ Hidden performance issues (only show up after drywall is installed)

💸 Expensive retrofits (ripping out ceilings to fix airflow problems)

🔍 Poor air quality (flex ducts are harder to clean)

🔌 Higher energy bills (fans work overtime to compensate)

“We won’t know if these diffusers are getting 5 CFM instead of 150 until someone complains their room feels like a sauna.”

— Kenneth Shultz, PE’s

Why TAB (Testing, Adjusting, and Balancing) Matters

TAB ensures that every room gets the right amount of airflow. It’s a critical quality control step before ceilings are closed up.

Without TAB:

There’s no proof that the HVAC system works as designed.

You can’t catch imbalances or airflow issues early.

Occupants are the first “testers”—usually by complaining.

“TAB isn’t a luxury—it’s insurance against invisible failures.”

Flex Duct: The Do’s and Don’ts

Length: Keep it under 6 feet—one bend max.

Support: Hang every 5 feet horizontal, 6 feet vertical. Limit sag.

Extension: Pull fully taut—no bunching or compression.

Bend Radius: Keep bends wide—at least 1 duct diameter.

Use Case: Use only as a short connector between rigid duct and diffuser—not the whole system!

What the Experts Are Saying

Here’s what MEP pros in the LinkedIn thread had to say:

🔧 “Flex isn’t the villain—misuse is.”

“It’s fine in the right hands, used the right way.” – John Chavez

Flexible ducts can work well if you follow the code, pull them taut, support them properly, and keep them short.

💰 “Low-bid culture leads to bad work.”

“Piece-rate installers get paid by the foot—not by quality.” – Darrell Hayes

Contractors often use flex duct because it’s cheap and fast. But poor installation leads to expensive callbacks—and the building owner pays the price.

🔍 “Commissioning and TAB need teeth.”

“Too many TAB reports skip key info like motor speeds and temperatures.” – Brad Miccio

Real commissioning means qualified professionals, robust reports, and active involvement from owners. It’s not a box to check—it’s how you prevent disaster.

🧠 “Tribal knowledge is gold—share it.”

“There’s more wisdom in comment sections than in most manuals.” – Nick Heim

The conversation inspired Kenneth Shultz to consider turning the best advice into a one-pager for clients. Every mistake shared can prevent future ones.

🏗️ “Better design avoids the problem.”

“Bulkheads and dropped ceilings are better than flex duct mazes.” – Kenneth Shultz, PE

Too often, architectural designs leave no room for proper ductwork. The fix? Coordinate early, plan for rigid ducts, and design for maintenance and performance—not just aesthetics.

Lessons Learned

Flex duct can work—but only if installed correctly, and in short runs.

Cutting corners on material and skipping TAB usually leads to higher costs later.

Commissioning is critical. Don’t skip it.

Good MEP design requires space, planning, and oversight.

MEP Tip to Live By:

“Cheap decisions are rarely free. Plan it right, or pay to fix it later.”

Final Thoughts

This article was adapted from a LinkedIn discussion led by Kenneth Shultz, PE. It combines code requirements, professional insights, and real-world experience to explain why flexible duct must be used carefully—and why commissioning and TAB are non-negotiable for quality HVAC systems.

For MEP for Dummies, it’s not just about ductwork—it’s about the value of thoughtful design, teamwork, and standing firm against the "race to the bottom."